- Great Value: Excellent performance at a cost effective price.

- Excellent Seam Strength: Heat-welded seams provide greater seam strength to taped and other seams.

- Long-term Weathering: Excellent long-term heat and UV resistance.

- Energy Saving: Highly reflective and emissive white surface can help reduce energy costs and urban heat island effect.

- Inherently Flexible: No need for plasticizers.

- Naturally Fungal Resistant: Doesn’t require biocides.

- Versatile Application Methods: Including high-performance roofs requiring high wind uplift, increased puncture resistance, or quick economical systems.

- Home

- Commercial

- TPO

- TPO | GAF

TPO | GAF

Click to Call: 1-888-243-7626

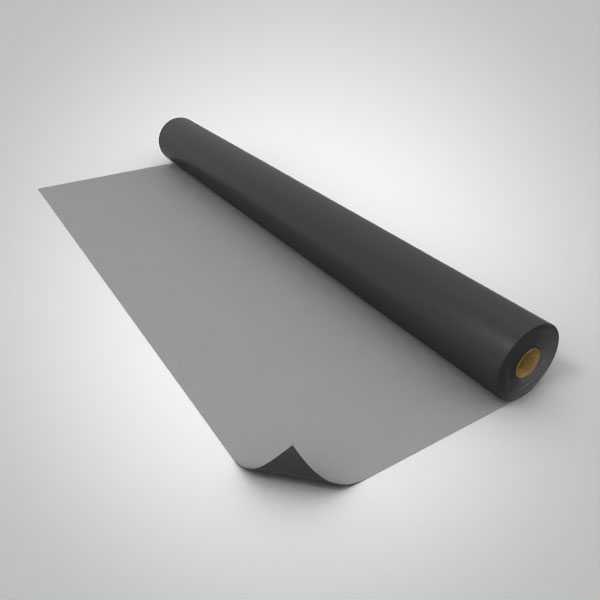

Short for thermoplastic polyolefin, TPO is a single-ply roofing membrane that offers excellent performance at a cost-effective price. Heat-welded seams provide superior strength. TPO's long-term heat, UV, and natural fungal resistance, plus flexibility without need for plasticizers also make TPO a reliable low-slope roofing system.

- General Details

- Related Products

White | 60 mil. TPO Membrane

Specifications |

|

|---|---|

| Roll Size | 5' x 100' | 8' x 100' | 10' x 100' | 12' x 100' |

| Thickness | 0.060 mil (.00152 mm) [ASTM D751] |

| Breaking Strength | 305 lbf x 290 lbf (454 x 432 kg/m) [ASTM D751 Grab Method] |

| Tear Strength | 75 lbf x 130 lbf (111.8 x 193.7 kg/m) 8" x 8" (203 x 203 mm)[ASTM D751] |

| Puncture Strength | 380 lb. (172 kg) [ASTM 101C Method 2031] |

| Color | White |

Grey | 60 mil. TPO Membrane

Specifications |

|

|---|---|

| Roll Size | 5' x 100' | 10' x 100' |

| Thickness | 0.060 mil (.00152 mm) [ASTM D751] |

| Breaking Strength | 305 lbf x 290 lbf (454 x 432 kg/m) [ASTM D751 Grab Method] |

| Tear Strength | 75 lbf x 130 lbf (111.8 x 193.7 kg/m) 8" x 8" (203 x 203 mm)[ASTM D751] |

| Puncture Strength | 380 lb. (172 kg) [ASTM 101C Method 2031] |

| Color | Grey |

TPO Accessories

| SKU # | Product Name | Size | Packing Type |

|---|---|---|---|

| TPOUN55 | GAF Un-55 Detailing Membrane | 24" x 50' (100sqft) | Roll |

| TPORTA | GAF Roof Transition Anchor | Roll | |

| TPOCT6 | GAF TPO 6" Cover Tape | 6"x100' | Roll |

| TPOFS | GAF TPO Flashing Strip | 8"x100' | Roll |

| TPOFC | GAF TPO Fluted Corner White | 8" | Each |

| TPOIC | GAF TPO Inside Corner | 6" x 6" | Each |

| TPOSTW44 | GAF TPO Sq Tube Wrap | 4" x 4" | Each |

| TPOSTW46 | GAF TPO Sq Tube Wrap | 4" x 6" | Each |

| TPOSTW66 | GAF TPO Sq Tube Wrap | 6" x 6" | Each |

| TPOTJP | GAF TPO T Joint Patch | 4" x 4" | Each |

| TPOUC | GAF TPO Universal Corner | 4"x4" | Each |

| TPOVB | GAF TPO Vent Boot | 1" - 6" Diameter | Each |

| TPOCW135 | GAF TPO Corner Curb Wrap | 13.5" | Each |

| TPOCW195 | GAF TPO Corner Curb Wrap | 19.5" | Each |

| TPOCW255 | GAF TPO Corner Curb Wrap | 25.5" | Each |

| TPOCW315 | GAF TPO Corner Curb Wrap | 31.5" | Each |

| TPOSRPB1 | GAF TPO Split Pipe Boot | 1"- 2" Diameter | Each |

| TPOSRPB3 | GAF TPO Split Pipe Boot | 3"- 5" Diameter | Each |

| TPOSR PB6 | GAF TPO Split Pipe Boot | 6"- 8" Diameter | Each |

| TPOD2 | GAF TPO Drain | 2" Diameter | Each |

| TPOD3 | GAF TPO Drain | 3" Diameter | Each |

| TPOD4 | GAF TPO Drain | 4" Diameter | Each |

| TPOS4612 | GAF TPO Scupper | 4" x 6" x 12" | Each |

| TPOS81012 | GAF TPO Scupper | 8" x 10" x 12" | Each |

| TPOV8 | GAF TPO Vent | 8" | Each |

| TPOBA | GAF TPO Bonding Adhesive | 5 Gallon | Pail |

| TPOCES | GAF TPO Cut Edge Sealant | Tube | |

| TPOCW | GAF TPO Flexseal, White | Tube | |

| TPOP | GAF TPO Primer | 1 Gallon | Each |

| TPOSC | GAF TPO Seam Cleaner | 1 Gallon | Pail |

| TPOWB | GAF TPO Waterblock Mastic, Black | Tube | |

| ISO1548 | Poly ISO Insulation | 1.5" 4'x 8' | Sheet |

| HDRB1248 | Recovery Board 1/2" 4' x 8' | 1/2" 4' x 8' | Sheet |

| TPOWRGY | GAF TPO Walkway, Grey | 34.25" x 50.5" | Roll |

| TPOPSP | GAF TPO Pourable Sealer | 9" x 6" x 4" | Each |

| TPOPS | GAF TPO 2 Part Pourable Sealer, Grey | 1 Gallon | Pail |

| GLRFA | GAF Low Rise Adhesive | 1.5L | Cartridge |

| DTSSPGS | DrillTec 3" Steel Plates Standard Galvalume | 3" | Box |

| DTSP2B | DrillTec Barbed Steel Plate | 2" | Pail |

| RHINO BOND | Drilltex Rhinobond Plate, use #15 screws with these plates | Carton | |

| DTS121583 | DrillTec #12, Phillips Screws | 1 5/8" | Pail |

| DTS122143 | DrillTec #12, Phillips Screws | 2 1/4" | Pail |

| DTS122783 | DrillTec #12, 3" Phillips Screws | 3" | Pail |

| DTS123343 | DrillTec #12, 4" Phillips Screws | 4" | Pail |

| DTS1253 | DrillTec #12, Phillips Screws | 5" | Pail |

| DTS1263 | DrillTec #12, Phillips Screws | 6" | Pail |

| DTS143 | Drilltec #14 HD Phillips Screws | 3" | Carton |

| DTS14 4 | Drilltec #14 HD Phillips Screws | 4" | Carton |

| DTS14 5 | Drilltec #14 HD Phillips Screws | 5" | Carton |

| DTS146 | Drilltec #14 HD Phillips Screws | 6" | Carton |

| DTS153 | Drilltec #15, xHD Fastener | 3" | Carton |

| DTS154 | Drilltec #15, xHD Fastener | 4" | Carton |

| DTS155 | Drilltec #15, xHD Fastener | 5" | Carton |

| DTS156 | Drilltec #15, xHD Fastener | 6" | Carton |

| DTS157 | Drilltec #15, xHD Fastener | 7" | Carton |

System Benefits

6 Simple Application Types

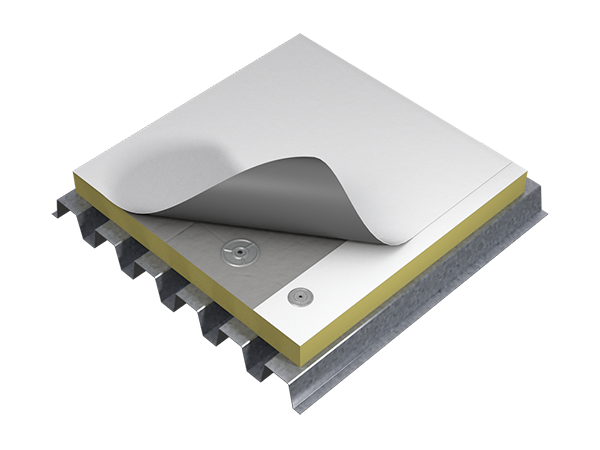

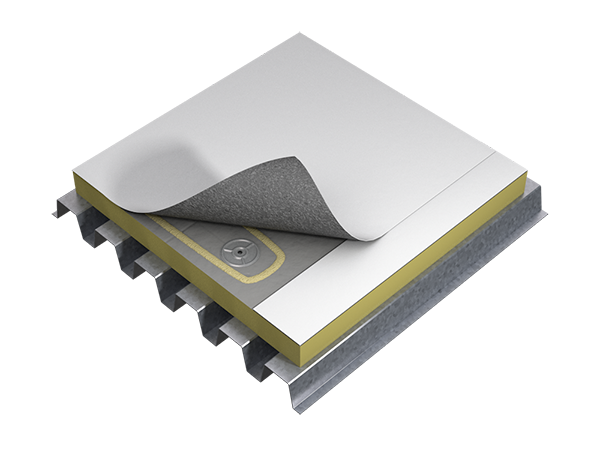

Mechanically Attached Smooth TPO

with Drill-Tec™ fasteners

Installing smooth TPO with fasteners in a mechanically attached system offers several benefits, including:

- Up to 50% faster installation compared to fully adhered smooth membrane installations

- Reliability and cost effectiveness

- Familiarity with the industry as the most common installation method in single-ply membranes

- Consistent installation in a wide variety of temperatures

- No sprayers or additional capital investments

- A great option for occupied buildings, as there is no odor from adhesives

While fully adhered systems have better wind uplift ratings, a mechanically attached system’s ratings can be increased by modifying the fastening pattern from 12″ on center to 6″on center. Be sure to refer to the GAF Drill-Tec™ Fastening Guide to choose the correct fasteners and plates for your application.

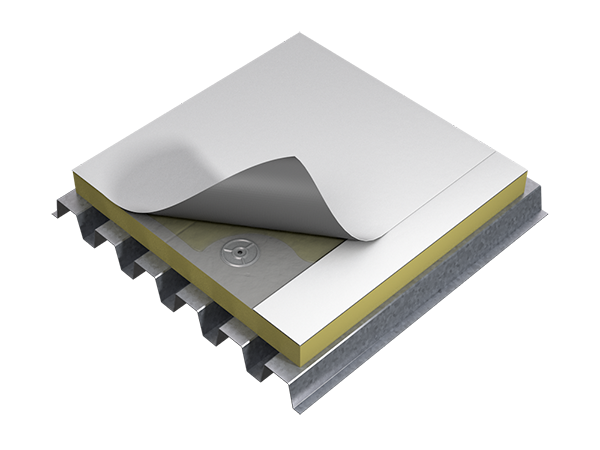

FULLY ADHERED SMOOTH TPO

with traditional bonding adhesive

Installing fully adhered EverGuard® Smooth TPO Systems offers several benefits, including:

- Longer guarantees compared to mechanically attached systems

- Excellent wind uplift ratings

- A uniform, smooth appearance

- Familiarity with workers, as this installation is common in the industry

- Minimizes thermal drift while acting as a vapour barrier

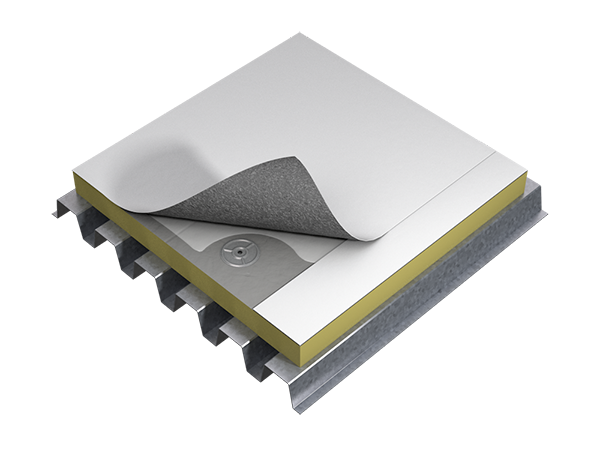

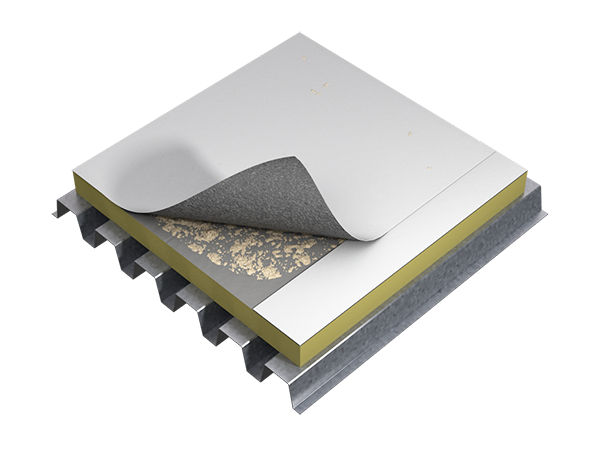

FULLY ADHERED FLEECE-BACK TPO

with WB181 wet lay-in

Installing fleece-back TPO with EverGuard® WB181 Bonding Adhesive offers several benefits, including:

- Up to 50% faster installation time than traditional smooth, fully adhered systems

- Reduced labor costs

- Low-VOC content with little-to-no odor, which reduces the disruption to building occupants

- Additional puncture resistance due to the fleece backing of EverGuard® membrane

ADHERED FLEECE-BACK TPO

with low-rise foam

Installing fleece-back TPO with low-rise foam roofing adhesive offers several benefits, including:

- Up to 50% faster installation time than traditional smooth, fully adhered systems

- Reduced labor costs

- Low-VOC content with little-to-no odor, which reduces the disruption to building occupants

- Additional puncture resistance due to the fleece backing of EverGuard® membrane

FULLY ADHERED FLEECE-BACK TPO

with GAF 2-part roofing adhesive

Installing fleece-back TPO with GAF 2-Part Roofing Adhesive offers several benefits, including:

- Up to 50% faster installation than traditional fully adhered, smooth systems (it’s as easy as watering your lawn)

- I ncreased productivity and smaller crews versus other attachment methods

- Up to 20 squares of coverage per set of containers

- Longer guarantees compared to mechanically attached systems

- No expensive equipment or maintenance

- Excellent wind uplift performance

- I ncreased puncture resistance due to the fleece backing of EverGuard® membrane

- Low-VOC content with low odor

- Substrate, membrane, and outside temperatures must be 40°F (4.4°C) and rising. Application temperatures above 50°F (10°C) are recommended to allow easier adhesive application.

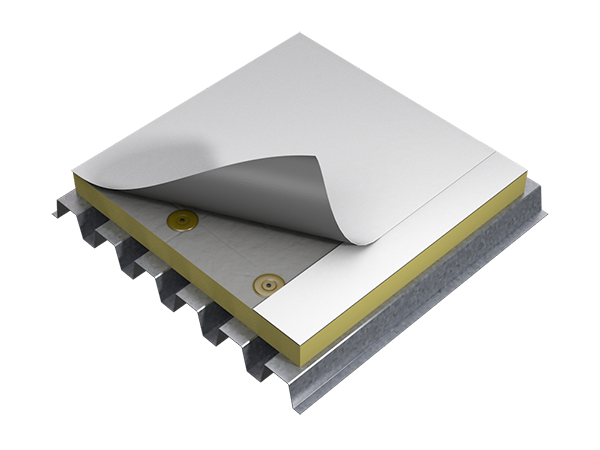

RHINOBOND® SYSTEM

Installing smooth TPO with the RhinoBond®† Attachment System offers several benefits, including:

- A fast and easy installation

- Smaller crews and install time, with up to 50% faster installation by adding a second machine

- Quick dry-in, as membrane seams can be welded before RhinoBond® Plates are bonded

Warranty Program

Please visit GAF’s website for information pertaining EVERGAURD TPO WARRANTIES.

Have a question?

Don’t see a specific product listed here? We may still be able to help. Please contact us using the form below and a Herman’s representative will get back to you shortly.

TPO | GenFlex

GenFlex lives to tackle – and solve – the toughest challenges in roofing. The result is a full line of proven, durable roofing systems and components that provide you with quality, ease of installation and complete warranty coverage. Because when it comes to meeting your needs, GenFlex just “gets it.”